An AI agent automates the complex BOM process in footwear manufacturing, boosting speed and operational efficiency

An AI agent automates the complex BOM process in footwear manufacturing, boosting speed and operational efficiency

Visual component recognition

Smart document reading

Industry:

Manufacturing

Delivery:

6 months

Services Used:

Our client is a global footwear manufacturing company with tens of thousands of employees and multiple production facilities. The company produces shoes for many of the world’s leading footwear brands, based on pre-designed models provided by the brands themselves.

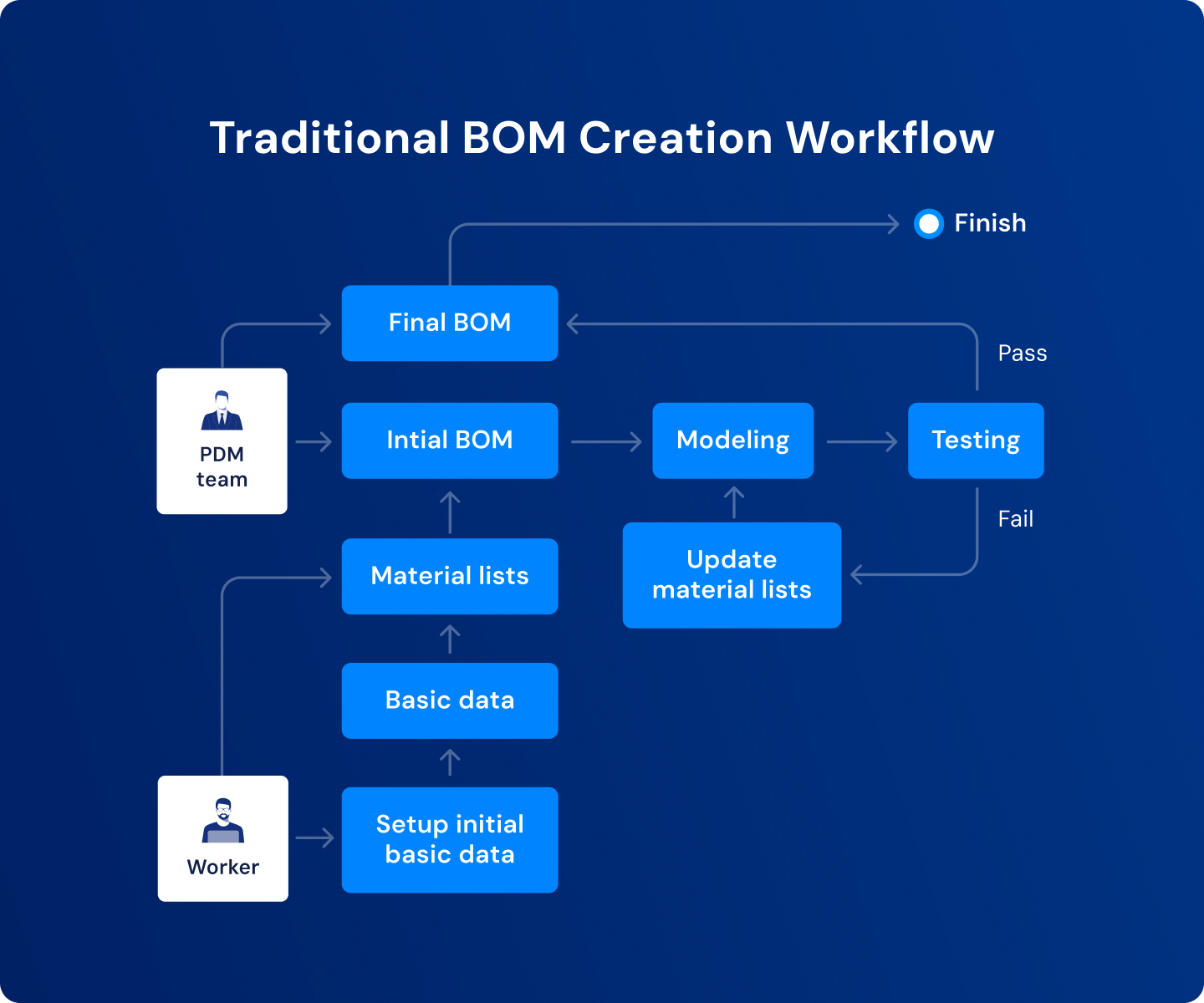

The production of a pair of shoes involves numerous steps and teams. A key part of this process is creating the Bill of Materials (BOM), which requires input from multiple departments based on supplied design specifications.

Therefore, the client needed an AI-driven solution to streamline this process and reduce manual effort. Given Ekotek’s track record in delivering AI solutions for the manufacturing sector, they selected us as their trusted technology partner.

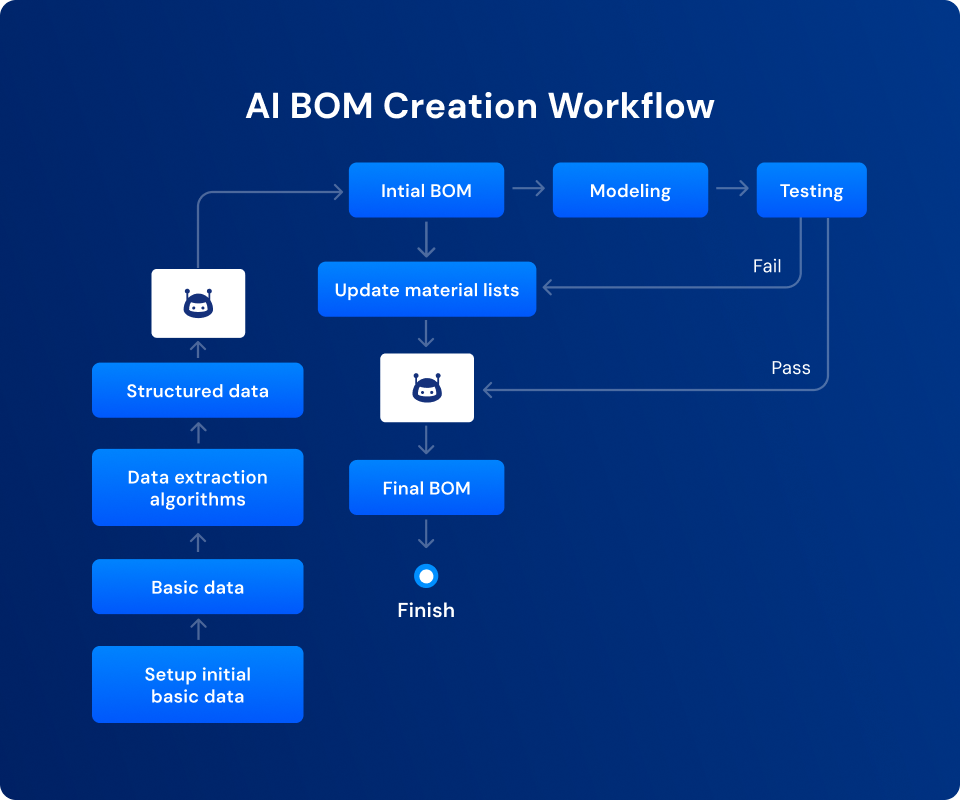

Ekotek developed a tailored AI agent to support the client’s production workflow and automate the BOM creation process. This AI agent integrates Computer Vision and Natural Language Processing (NLP) technologies to meet the specific needs of the client.

By combining these technologies, the AI agent can autonomously parse documents and images, extract relevant information, and suggest or even generate BOM files without human intervention.

Ekotek successfully delivered the AI agent to the client, significantly reducing manual work for their teams. The solution streamlines the design and BOM creation process, improves accuracy, and enhances production efficiency.

Key features of the AI Agent:

🔎 Looking for something similar? Explore our services

Ready for your own success story?

Dylan Dong Do is a seasoned leader with over 15 years of experience in business management across both product and ITO companies. Under his leadership, Ekotek has grown from a small team to a thriving organization of over 200 skilled professionals in just 5 years.

Throughout Dylan’s career, he has achieved remarkable success. In 2009, he played a key role in developing batdongsan.com.vn, establishing it as Vietnam’s top real estate listing platform. In 2018, Dylan was promoted to Chief Operating Officer of VTI, driving VTI to exponential growth from a 30-member team to a robust force of over 300 staff.

With a desire to integrate technological advancements into everyday life, Dylan Dong Do founded Ekotek. He consistently updates his knowledge and skills in advanced technology to orient the company, ensuring that it stays at global trends and better serves the needs of customers.