An AI agent automates the complex BOM process in footwear manufacturing, boosting speed and operational efficiency

An AI agent automates the complex BOM process in footwear manufacturing, boosting speed and operational efficiency

Visual component recognition

Smart document reading

산업

Manufacturing

배송

6 months

Our client is a global footwear manufacturing company with tens of thousands of employees and multiple production facilities. The company produces shoes for many of the world’s leading footwear brands, based on pre-designed models provided by the brands themselves.

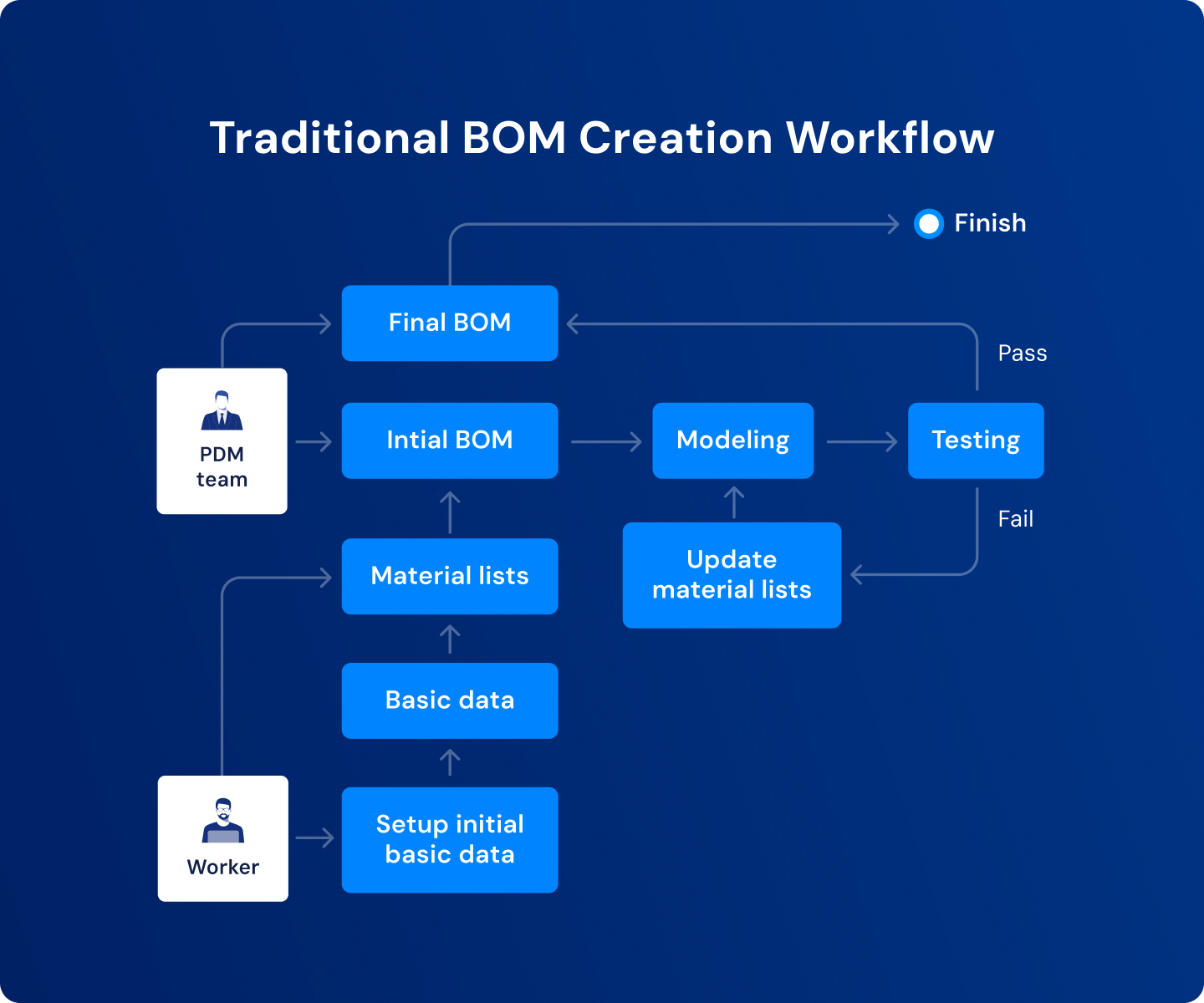

The production of a pair of shoes involves numerous steps and teams. A key part of this process is creating the Bill of Materials (BOM), which requires input from multiple departments based on supplied design specifications.

Therefore, the client needed an AI-driven solution to streamline this process and reduce manual effort. Given Ekotek’s track record in delivering AI solutions for the manufacturing sector, they selected us as their trusted technology partner.

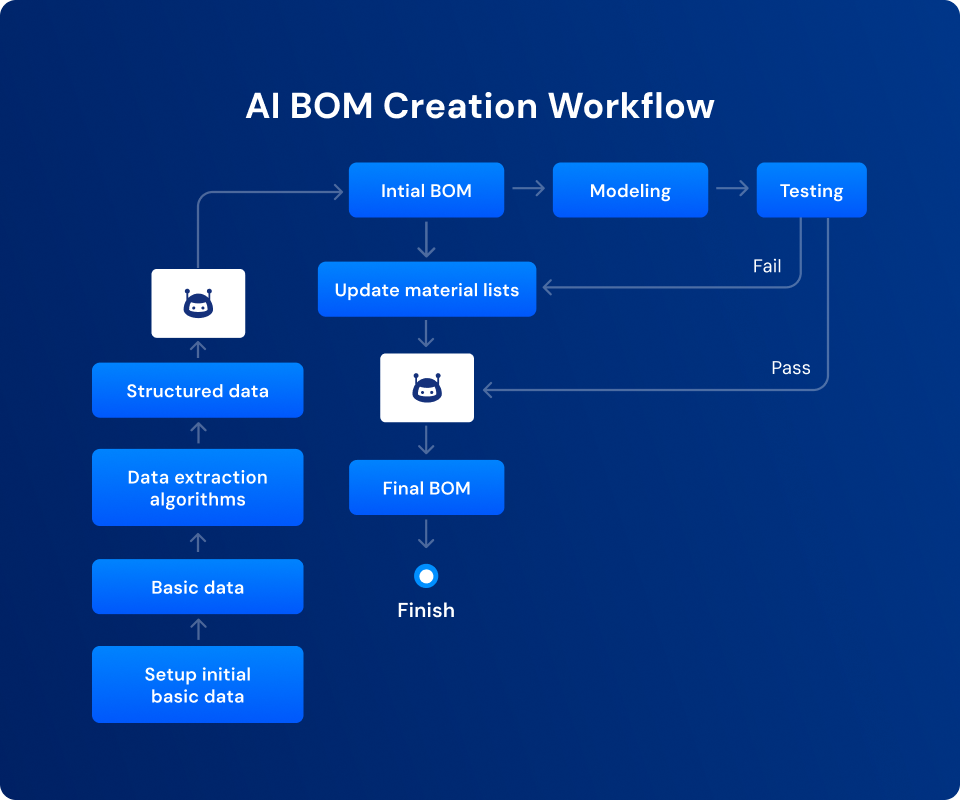

Ekotek developed a tailored AI agent to support the client’s production workflow and automate the BOM creation process. This AI agent integrates Computer Vision and Natural Language Processing (NLP) technologies to meet the specific needs of the client.

By combining these technologies, the AI agent can autonomously parse documents and images, extract relevant information, and suggest or even generate BOM files without human intervention.

Ekotek successfully delivered the AI agent to the client, significantly reducing manual work for their teams. The solution streamlines the design and BOM creation process, improves accuracy, and enhances production efficiency.

Key features of the AI Agent:

🔎 Looking for something similar? Explore our services

자신만의 성공 스토리를 시작할 준비가 되셨나요?